It is with great pleasure that HNS Fume & Dust Control Pty Ltd introduce to you our 'Muck Sucker' electronic air cleaner.

The 'Muck Sucker' units are fully designed and manufactured in Australia, therefore there are no expensive import costs and they are an effective way of reducing industrial and commercial pollution, thus producing a safer, healthier and more pleasant working environment, with the added benefit of low energy running costs. Tests on filtration efficiency results on No.1 dust is not less than 91%.

The 'Muck Sucker' is an electronic air cleaning system that captures the air borne fumes/particles generated during commercial and industrial processes, collects the fumes/particles from the air stream and returns the clean air back into the work space.

The system is specially designed to clear particles in the air that are inhaled and not necessarily expelled from the body.

The 'Muck Sucker' can be tailored to control most polluted air applications including welding fumes, grinding residues, oil mists, cooking smoke and machine emissions that can be cleaned and the air returned to provide a healthier environment.

HNS Fume & Dust Control Pty Ltd provides complete design, engineering and service to control any of the above problems. Whatever your air pollution problem, we will give you the right answer.

Our units have now been installed widely throughout Australia for well over 15 years and we have always enjoyed a good co-operative relationship with the Melbourne City Council people.

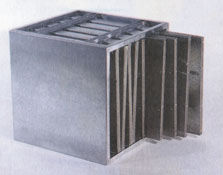

The 'Muck Sucker' unit is the only electonic air cleaner housed in durable stainless steel and is generally a self-contained system, but can be inserted in existing extraction and air-conditioning systems as stand alone filters comprising the following sections.

Pre-filter section used to house slide in filters for the removal of large particles such as fibres etc.

An Ioninzing cell which charges the air stream with 12kv - DC and causes particulate matter in the air stream to be drawn to and collect on to earth potential plates.

Collecting cells, which are charged at 6kv - DC with every second plate earth potential, which collects the particulate matter down to .01 micron size.

Section 4

Section 4A deep bed carbon cell, which is designed to absorb the odour component of the contaminants is fitted directly after the 'Muck Sucker' which removes grease and dirt from the air stream, does not then expose the carbon cell to these contaminants thus increasing its life dramatically.

We have many clients replacing activated carbon granules every 3 to 4 years, where as without the electronic air cleaner you may need to change the carbon every 3 to 6 months.

Our standard activated granule type deep bed carbon filters are re-usable and not the slide in throw away type activated carbon filters which block up very quickly and do not last.

A fan unit, which is often built into the cabinet but may be mounted separately depending on specific operations.

By fitting these units, the smoke and odours are removed and air discharges do not necessarily have to exit via the roof as this is sometimes impossible to reach, especially in cooking applications in the inner city areas.

We have had occasions when fitting these units, where they have made the vendor able to operate a business when they were located on the ground floor of a high level building, above or adjacent and taking the ducting to the roof was impossible or the costs were extremely expensive.

The Pre-filters, Ionizing cells and Collector cells are easily removed and can be steam cleaned or washed in commercial dishwasher.

A visible set of operating lights alerts the operator when these items require servicing/cleaning.

When a unit is commissioned we usually engage the owner/operator in a service contract to ensure the 'Muck Sucker' is operating at maximum levels.

After a 'Muck Sucker' unit is installed/commissioned we usually engage the owner/operator in a service contract which is then followed up by our people. Generally this is at 3-monthly intervals depending on the work load of the unit.

We have an experienced team of service people available to clean and replace parts as required and they are trained to ensure that the system is working correctly before they leave the site.

| Model | Air Flow Lt/sec | Length | Width | Height | Weight Kg |

| MS1000SC | 500 | 1490mm | 500mm | 590mm | 110 |

| MS2000SC | 1000 | 1490mm | 935mm | 590mm | 160 |

| MS4000SC | 2000 | 1590mm | 935mm | 1180mm | 260 |

| Mobile | 300 | 1050mm | 595mm | 1020mm | 150 |

| Standard Power Packs Are Duel Voltage | |||||

| Motor Sizing To Customers Requirements | |||||

| Model | Air Flow Lt/sec | Length | Width | Height | Weight Kg |

| MS1000SC/CARB WITH FAN | 500 | 2020mm | 500mm | 590mm | 190 |

| MS2000SC/CARB WITH FAN | 1000 | 2020mm | 935mm | 590mm | 310 |

| MS4000SC/CARB WITH FAN | 2000 | 2020mm | 935mm | 1180mm | 560 |

| MS6000CO/CARB NO FAN | 3000 | 1180mm | 935mm | 1770mm | 690 |

| MS8000CO/CARB NO FAN | 4000 | 1180mm | 935mm | 2360mm | 920 |

| Standard Power Packs Are Duel Voltage | |||||

| Motor Sizing To Customers Requirements | |||||

SC - Contains Fan Unit

CO - Collector Cell Only/No Fan